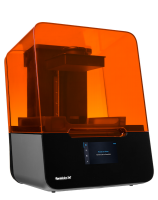

Formlabs Form 3

The Form 3 by Formlabs is a versatile and professional 3D printer, designed for producing small, accurate and detailed prints in a variety of materials.

The Form 3 uses Low Force Stereolithography (LFS); an advanced form of stereolithography (SLA) 3D printing technology that uses linear illumination and a flexible tank to turn liquid resin into flawless prints. The resulting output are consistent, highly repeatable 3D printed parts with an excellent surface finish.

With a build size of 145mm x 145mm x 185mm, the Form 3 features a re-engineered optical system, the Light Processing Unit, which maintains a precise, dense laser spot of 85 microns for accurate prints, and uses a newly designed Form 3 Resin Tank with a flexible base. The 3D printed parts have tear-away light-touch supports, for easy clean-up.

The Form 3 uses Formlabs 1 litre resin cartridges, in a range of materials*.

Key features of the Form 3 include:

Light-touch supports, that are easy to tear away

Precise, dense laser spot size of 85 microns for accurate, detail prints

Integrated sensors to monitor and maintain conditions for consistent performance

Versatility to print in a range of resins

The Form 3 has excellent connectivity via Ethernet, Wi-Fi and USB and is compatible with Windows, Mac and Linux operating systems. The print software, PreForm allows for management of the Form 3 within teams to monitor and manage print flow.

The Form 3 is compatible with the Form Wash and Form Cure for a streamlined post-processing.

Formlabs Form 3 Technical Specifications

Print Technology | Low Force Stereolithography (LFS) |

| Resin Fill System | Automated |

| Material(s) | Formlabs Resins 1 litre cartridges |

| Resin Cartridges | 1 |

Form 3 Dimensions Minimum Access Dimensions | 405mm (w) x 375mm (d) x 530mm (h) 15.9” (w) x 14.8” (d) x 20.9″ (h) |

| Weight | 17.5kg |

| Max Build Size | 145mm (w) x 145mm (d) x 185mm (h) 5.7” (w) x 5.7” (l) x 7.3” (h) |

| Layer Thickness (axis resolution) | 25 – 300 microns |

| Laser Spot Size (FWHM) | 85 microns 0.0033″ |

| Laser Power | One 250 mW laser |

| Supports | Auto-generated Light-touch removal |

| Operating Temperature | Auto-heats to 35°C |

| Temperature control | Air-heated print chamber |

| Design file input format | STL / OBJ |

| Power requirements | 100 – 240V, 2.5A, 50/60 Hz, 220 W |

| Laser specifications | 1 Light Processing Unit EN 60825-1:2007 certified Class 1 Laser Product 405 nm wavelength 250 mW power 85 micron (0.0033 in) laser spot |

| System requirements | Windows 7 (64-bit) onwards Mac OS X 10.10 onwards OpenGL 2.1 4GB RAM |

| Connectivity | Wi-Fi (2.4, 5 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Printer control | 5.5″ Interactive touch-screen 1280 x 720 resolution |

| Alerts | Touchscreen alerts SMS/email via Dashboard Two LED status indicators Speaker for audio alerts |

| PreForm Print Setup Features | One-click print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient for optimal print position Auto-mesh repair Auto-generation of supports Rotate, scale, duplicate and mirror Layer slicer for path inspection |

| Dashboard Printer Management Features | Manage prints and printers via the cloud Track resin and tank usage over time SMS and email alerts Create enterprise group accounts with admins to more easily share printers & control access |

Please note the Technical Specifications are provided by the Manufacturer and may be subject to change.