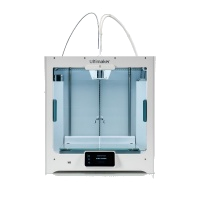

Ultimaker S5

The Ultimaker S5 is a large build volume, dual extrusion 3D printer with the versatility of printing in a wide range of different materials, making it ideal for a range of applications from rapid prototyping, large models, designs and props that require geometrical design freedom capabilities, to creating on-demand parts and manufacturing tools.

Large build volume

The Ultimaker S5 features a large maximum build area of 330mm x 240mm x 300mm with fully integrated hardware, software and materials configuration to create a smooth workflow.

Material versatility

With the versatility of the easily swappable Ultimaker print cores, the Ultimaker S5 is a dual extrusion 3D printer that can print in a range of build and support materials, in different nozzle diameters (0.4mm as standard, with 0.25mm, 0.6mm and 0.8mm options). The Ultimaker S5 can use a wide range of thermoplastics including PLA, Nylon, Polypropylene, Polycarbonate, TPU, Tough PLA, ABS and soluble support materials such as PVA and Breakaway Support, with preset configurations for Ultimaker materials.

Optimised for continued workflow

The S5 has a closed front and comes with enhanced bed levelling to generate an excellent first layer adhesion, with the continued functionality of continuously compensating during printing where required. The Ultimaker S5 features an optimised touch screen for better user experience and connectivity via Wi-FI, Ethernet or USB stick, with camera monitoring via the Ultimaker app or desktop. Furthermore, the new large build Ultimaker has an improved feeder system with a filament flow sensor to automatically pause, and notify, if material runs out.

Compatible with Windows, Mac and Linux operating systems.

Ultimaker S5 Technical Specification

| Print technology | Fused Filament Fabrication (FFF / FDM) |

| Extruder(s) | 2 – Dual extrusion with auto-nozzle lifting system and swappable print cores |

| Nozzle diameter | 0.4mm standard 0.25mm, 0.6mm, 0.8mm available separately |

| Supported filament(s) | 2.85mm diameter Optimised for: PLA, Tough PLA, Nylon, ABS, CPE, CPE+, PC, TPU 95A, PP, PVA, Breakaway Also supports third-party materials |

| Max build size | 330mm (w) x 240mm (d) x 300mm (h) 12.99″ (w) x 9.44″ (d) x 11.81″ (h) (Left or right nozzle, or dual extrusion) |

Ultimaker S5 physical dimensions (incl. Bowden tube & spoolholder) | 495mm (w) x 457mm (d) x 520mm (h) 19.48” (w) x 17.99″ (d) x 20.47″ (h) |

| Layer resolution | 0.25mm nozzle: 150 – 60 microns 0.4mm nozzle: 200 – 20 microns 0.6mm nozzle: 300 – 20 microns 0.8mm nozzle: 600 – 20 microns |

| XYZ accuracy | 6.9, 6.9, 2.5 micron |

| Nozzle temperature | 180°C to 280°C |

| Weight | 20.6kg |

| Build plate | Heated glass build plate (20°C to 140°C) |

| Build plate levelling | Active levelling |

| Build speed | < 24 mm3/s |

| Nozzle heat up time | < 2 mins |

| Build plate heat up time | < 4 mins (from 20°C to 60°C) |

| Print support structures | Dissolvable support structures or break away support materials with pliers or cutters |

| Power rating | 500W |

| Operating sound | 50 dBA |

| Material recognition | Auto-recognition with NFC scanner when used with Ultimaker NFC material spools |

| Display & monitoring | 4.7″ (119mm) colour touchscreen Live camera (view from desktop or app) |

| Supported file types | Ultimaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UPF |

| Supplied software | Ultimaker Cura, free print preparation software Cura Connect, free printer management solution Ultimaker Cloud, enables remote printing |

Supported operating systems Plugin Integration | Windows, Mac OS, Linux SolidWorks, Siemens NX |

| Connectivity / File transfer | WiFi, LAN or USB port |

| Operating ambient temperature | 15°C to 32°C, 10 – 90% RH non condensing |

| Manufacturer warranty | 12 months |

Please note the Technical Specifications are provided by the Manufacturer and may be subject to change.